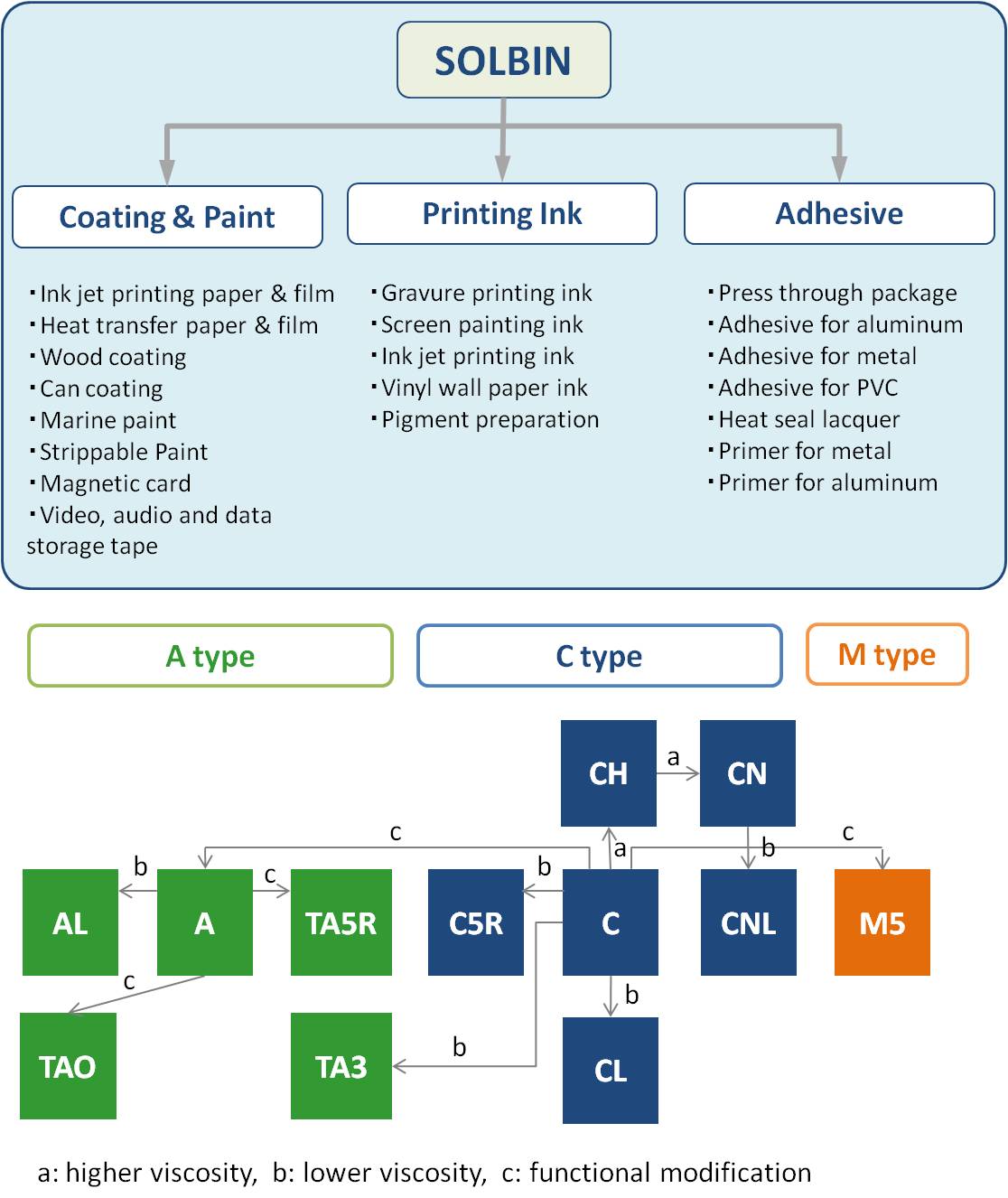

Vinyl chloride-Vinyl acetate based copolymer SOLBIN

SOLBIN is a modified resin that combines the toughness and chemical resistance of vinyl chloride, the strong adhesiveness and plasticity of vinyl acetate, and other polar groups that enhance adhesive properties and solubility. Due to its many outstanding characteristics, including its lack of odor or taste and high resistance to water absorption, Solbin is used as a binder for magnetic cards and tapes, as a coating agent for beverage cans and moisture-proof cellophanes, and also as part of various paints, inks, and adhesives.

Characteristics of SOLBIN

SOLBIN is a copolymer resin prepared from vinyl chloride, vinyl acetate, and other materials. It has the following characteristics:

- Dissolves in organic solvents such as ketone and ester.

- Forms an odorless, tasteless, and transparent film.

- Highly resistant to chemicals such as acids, alkalis, and salt water.

- Forms a coating film that is highly resistant to water.

- Coating films are fire-retardant and self-extinguishing.

- Coating films are thermoplastic and heat-sealable.

- Highly compatible with urethane and melamine resins.

- Grades with hydrophilic groups favorably disperse inorganic pigments such as magnetic powder.

- Grades with hydroxyl groups react with isocyanate to form cross-links.

Product types

Characteristics of product line

Printing Ink

| Grade | Composition(VC) | Composition(VAc) | Composition(Other) (Wt%) |

Degree of polymerization | Average molecular Mn (×104) |

Glass-transition temperature (℃) |

Viscosity(mPa・s/25℃) | K-value | Features |

|---|---|---|---|---|---|---|---|---|---|

| A | 92 | 3 | 5 Vinyl alcohol | 420 | 3.5 | 74 | 220 | 48 | Standard grade of saponified type, good compatibility with various resins |

| AL | 92.5 | 2.5 | 5 Vinyl alcohol | 300 | 2.7 | 74 | 70 | 42 | Low viscosity type |

| ALLP | 92 | 1 | 7 Vinyl alcohol | 260 | 1.4 | 75 | 55 | 39 | Low viscosity/high vinyl alcohol content type of AL |

| AP | 92.5 | 1 | 6.5 Vinyl alcohol | 430 | 2.9 | 75 | 210 | 49 | High vinyl alcohol content type |

| C | 87 | 13 | 420 | 3.6 | 70 | 150 | 48 | Standard grade of bipolymer | |

| C5R | 79 | 21 | 350 | 2.6 | 64 | 60 | 45 | Specialized type in solubility and flexibility | |

| CH | 86 | 14 | 650 | 5.0 | 70 | 700 | 57 | High viscosity type, good heat resistance / weather resistance | |

| CL | 86 | 14 | 300 | 2.5 | 68 | 60 | 42 | Low viscosity type, good solubility | |

| CLL3 | 83 | 17 | 260 | 1.4 | 66 | 30 | 39 | Specialized type for inkjet | |

| CN | 89 | 11 | 750 | 4.2 | 73 | 60 | High vinyl chloride content type, high viscosity, high coating film strength | ||

| CNL | 90 | 10 | 200 | 1.6 | 69 | 30 | 33 | Low viscosity type of CN, good solubility | |

| M5 | 85 | 14 | 1 Dicarboxylic acid | 430 | 3.3 | 70 | 130 | 49 | Good adhesion to metal and aluminum |

| M5R | 77 | 22 | 1 Dicarboxylic acid | 390 | 3.2 | 64 | 70 | 47 | M5 with high vinyl acetate content, good heat sealability at low temperatures |

| TA3 | 83 | 4 | 13 Hydroxyalkyl acrylate | 350 | 3.2 | 64 | 80 | 45 | Low viscosity type with good pigment dispersibility/thermal stability |

| TA5R | 87.5 | 1 | 11.5 Vinyl alcohol | 300 | 2.9 | 75 | 130 | 42 | High vinyl alcohol content type, specialized type in dispersibility/solubility |

| TAO | 91 | 2 | 7 Vinyl alcohol | 360 | 2.0 | 76 | 230 | 45 | Good dispersibility in pigments and magnetic powder |

Coating&Paint

| Grade | Composition(VC) | Composition(VAc) | Composition(Other) (Wt%) |

Degree of polymerization | Average molecular Mn (×104) |

Glass-transition temperature (℃) |

Viscosity(mPa・s/25℃) | K-value | Features |

|---|---|---|---|---|---|---|---|---|---|

| A | 92 | 3 | 5 Vinyl alcohol | 420 | 3.5 | 74 | 220 | 48 | Standard grade of saponified type, good compatibility with various resins |

| AL | 92.5 | 2.5 | 5 Vinyl alcohol | 300 | 2.7 | 74 | 70 | 42 | Low viscosity type |

| C | 87 | 13 | 420 | 3.6 | 70 | 150 | 48 | Standard grade of bipolymer | |

| C5R | 79 | 21 | 350 | 2.6 | 64 | 60 | 45 | Specialized type in solubility and flexibility | |

| CH | 86 | 14 | 650 | 5.0 | 70 | 700 | 57 | High viscosity type, good heat resistance / weather resistance | |

| CL | 86 | 14 | 300 | 2.5 | 68 | 60 | 42 | Low viscosity type, good solubility | |

| CN | 89 | 11 | 750 | 4.2 | 73 | 60 | High vinyl chloride content type, high viscosity, high coating film strength | ||

| M5 | 85 | 14 | 1 Dicarboxylic acid | 430 | 3.3 | 70 | 130 | 49 | Good adhesion to metal and aluminum |

| TA3 | 83 | 4 | 13 Hydroxyalkyl acrylate | 350 | 3.2 | 64 | 80 | 45 | Low viscosity type with good pigment dispersibility/thermal stability |

| TA5R | 87.5 | 1 | 11.5 Vinyl alcohol | 300 | 2.9 | 75 | 130 | 42 | High vinyl alcohol content type, specialized type in dispersibility/solubility |

| TAO | 91 | 2 | 7 Vinyl alcohol | 360 | 2.0 | 76 | 230 | 45 | Good dispersibility in pigments and magnetic powder |

Adhesive

| Grade | Composition(VC) | Composition(VAc) | Composition(Other) (Wt%) |

Degree of polymerization | Average molecular Mn (×104) |

Glass-transition temperature (℃) |

Viscosity(mPa・s/25℃) | K-value | Features |

|---|---|---|---|---|---|---|---|---|---|

| A | 92 | 3 | 5 Vinyl alcohol | 420 | 3.5 | 74 | 220 | 48 | Standard grade of saponified type, good compatibility with various resins |

| AL | 92.5 | 2.5 | 5 Vinyl alcohol | 300 | 2.7 | 74 | 70 | 42 | Low viscosity type |

| C | 87 | 13 | 420 | 3.6 | 70 | 150 | 48 | Standard grade of bipolymer | |

| C5R | 79 | 21 | 350 | 2.6 | 64 | 60 | 45 | Specialized type in solubility and flexibility | |

| CH | 86 | 14 | 650 | 5.0 | 70 | 700 | 57 | High viscosity type, good heat resistance / weather resistance | |

| CL | 86 | 14 | 300 | 2.5 | 68 | 60 | 42 | Low viscosity type, good solubility | |

| CN | 89 | 11 | 750 | 4.2 | 73 | 60 | High vinyl chloride content type, high viscosity, high coating film strength | ||

| M5 | 85 | 14 | 1 Dicarboxylic acid | 430 | 3.3 | 70 | 130 | 49 | Good adhesion to metal and aluminum |

| M5R | 77 | 22 | 1 Dicarboxylic acid | 390 | 3.2 | 64 | 70 | 47 | M5 with high vinyl acetate content, good heat sealability at low temperatures |

Note: The values in the table are representative values, not standard values.

*1 Resin concentration; 20wt%, solvent; MIBK/toluene=1/1 / measured by Type B viscometer(25℃)

Properties of SOLBIN

(1) SOLBIN's representative powder properties

| Item | C | A | M5 | Test method |

|---|---|---|---|---|

| Particle size | 100-120μ | 100-120μ | 100-120μ | Optical tansmission particle size distribution meter |

| Sieve test 100 mesh pass |

90% | 90% | 60% | Sieve test 100 mesh pass 149μ* |

| Sieve test 200 mesh pass |

10% | 5% | 10% | 200 mesh pass 74μ * |

| Specific gravity | 1.4 | 1.4 | 1.4 | |

| Bulk specific gravity | 0.8 | 0.7 | 0.7 | JIS K-6721 |

| Repose angle | 23-25° | 25-28° | 40-50° | |

| Electrification | * Maximum: +1500V * After 10 seconds: +400V * After 1 minute: 0 |

* Minimum: -1500V * After 30 seconds: -1100V * After 1 minute: -250V |

Statiron M static electricity meter(20℃x60%RH) |

Note: JIS Standard sieve.

(2) SOLBIN's representative film properties

Physical properties

| Item | C | A | M5 | Test method |

|---|---|---|---|---|

| Moisture permeability of film (g/m2·day) |

Approx. 170 | Approx. 130 | Approx. 180 | JIS Z-0208 40±0.1℃ 90±2%RH 0.02-0.03mm thickness |

| Physical properties Elongation (%) Tensile strength (kg/mm2) Young's modulus (dyne/cm2) |

1-2 4-6 2-3x1010 |

1-2 4-6 2-3x1010 |

2-3 4-5 2-3x1010 |

23±1℃ 80±2%RH |

Chemical resistance

| Test item | Chemical | Immersion time | C | A | M5 |

|---|---|---|---|---|---|

| Acid resistance | 10% HNO3 | 144 hours | Excellent | Excellent | Excellent |

| Alkali resistance | 10% NaOH | 144 hours | Excellent | Excellent | Excellent |

| Water resistance | Pure water | 144 hours | Excellent | Excellent | Excellent |

| Salt water resistance | 5% salt water | 144 hours | Excellent | Excellent | Excellent |

| Alcohol resistance | 60% ethyl alcohol | 18 hours | Excellent | Excellent | Excellent |

| Heat resistance | Pure water 77℃ | 45 minutes | Excellent | Slightly whitened | Slightly whitened |

(3) Organic solvents used in SOLBIN

| Temperature | 25℃ | 50℃ | Temperature | 25℃ | 50℃ | ||

|---|---|---|---|---|---|---|---|

| Solvent | Methanol | × | × | Solvent | Cellosolve | △ | △ |

| IPA | × | × | Acetone | ○ | ○ | ||

| n-Butanol | × | × | MEK | ○ | ○ | ||

| Methyl acetate | × | ○ | MIBK | ○ | ○ | ||

| Ethyl acetate | △ | ○ | Isophorone | ○ | ○ | ||

| Butyl acetate | △ | ○ | Cyclohexanone | ○ | ○ | ||

| DIDP | △ | △ | Ethylene chloride | ○ | ○ | ||

| DINP | △ | △ | Toluene | × | × | ||

| Tetrahydrofuran | ○ | ○ | Solvesso #150 | × | △ | ||

| Dioxane | ○ | ○ | Aliphatic carbide | × | × | ||

- ○: Soluble

- △: Swells or partially insoluble

- x: Insoluble