What are emulsions?

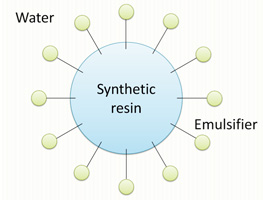

Emulsions are liquid materials generally with a white to milky white color, consisting of water and synthetic resin particles that are uniformly dispersed in the water.

In ordinary emulsions, these particles are stabilized by emulsifiers.

Our emulsion product family includes soap-free type emulsions, in which particles are stabilized without using emulsifiers.

Features of emulsions

- Safety and environmental friendliness ensured by using water as a solvent

- Viscosity can be easily adjusted

- Suitability for gluing and coating applications derived from emulsion's property of forming a film when dried

- Excellent miscibility with pigments, solvents, additives, etc.

- Size of synthetic resin particles, ranging from several tens to several thousands of nanometers

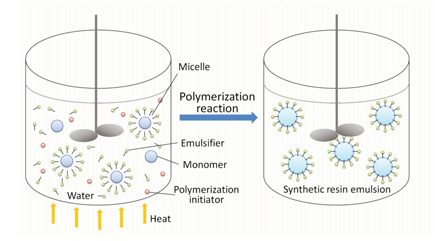

Method of manufacturing emulsions

First, monomers (e.g., vinyl chloride, vinyl acetate, acrylic, silicone) as a raw material for a synthetic resin are uniformly dispersed in water.

Then, the monomers migrate toward emulsifier aggregates called micelles that are dispersed in the water.

When a polymerization reaction initiator enters these micelles, the initiator heats the micelles, causing a polymerization reaction.

The monomers that have reacted become synthetic resin particles and are uniformly dispersed in the water.

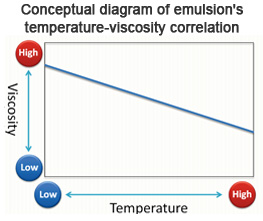

Viscosity of emulsions

The viscosity of emulsions varies depending on the temperature.

As the temperature decreases, the viscosity increases. Some emulsions exhibit a considerably high viscosity at a temperature of not more than 5°C.

In addition, emulsions may be frozen at a temperature of not more than 0°C because water is used as a solvent.

By adding water, the viscosity can be adjusted to a lower viscosity.

When needing to reduce the viscosity, please use this method.

To increase the viscosity, please use a commercially available emulsion thickener.